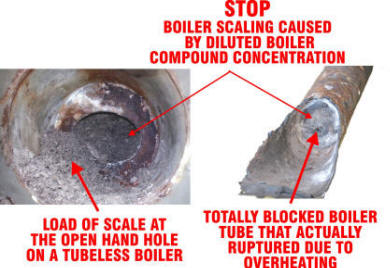

The EZLEVEL prevents premature piping failure as well as

boiler scaling by replacing that troublesome relic, the ball-float valve.

The ball-float valve maintains the level of water in the return tank.

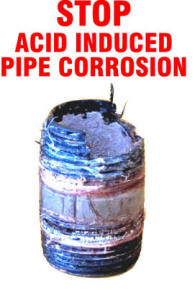

Ball-float valves are known for leaking and/or failing open. This allows

fresh water to continuously leak into the return tank. This fresh water

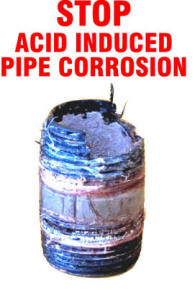

contains lots of free oxygen which combines with carbon dioxide to create

carbonic acid. Carbonic acid destroys pipe work and boiler internals. In

addition this continuous leakage of fresh water dilutes the boiler compound

resulting in scale formation.

![]()